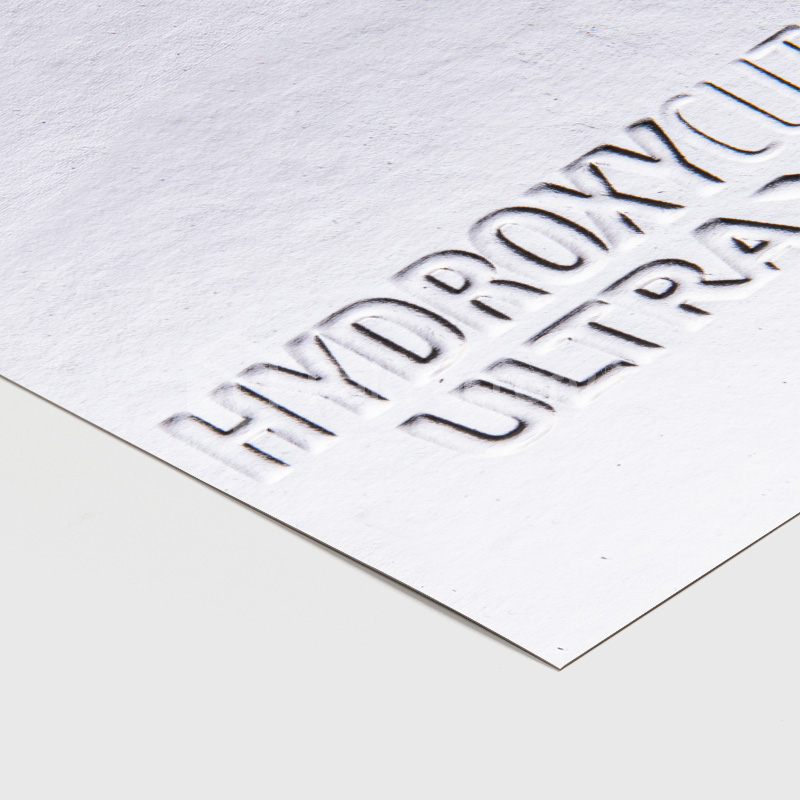

Blind embossing presses logos and text into paperboard to create a 3D design that customers can see and feel. Ideal for creating cutting edge artwork designs, embossing is popular across a wide rang of industries including apparel, cosmetics and luxury goods.

- 3D design

- Time efficient

- Ideal for enhancing logos, text and designs

Best Used With

Overview

Embossing uses no ink and dies are pressed onto the paperboard to create a 3D look, allowing customers to not only see designs, text and logos, but feel them too. Ideal for corrugated and folding carton packaging, blind embossing is a unique and subtle way to draw attention to key elements of your packaging design.

Foil Stamping Process

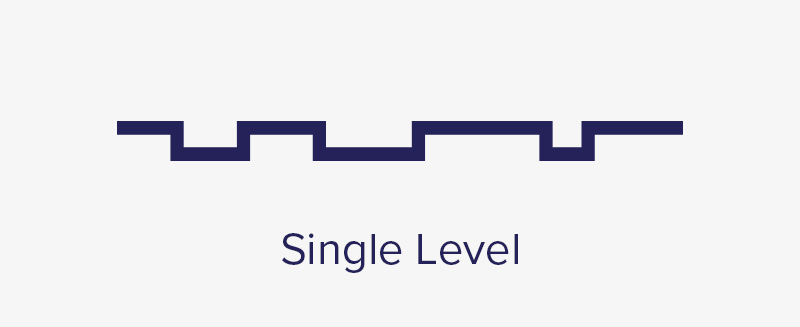

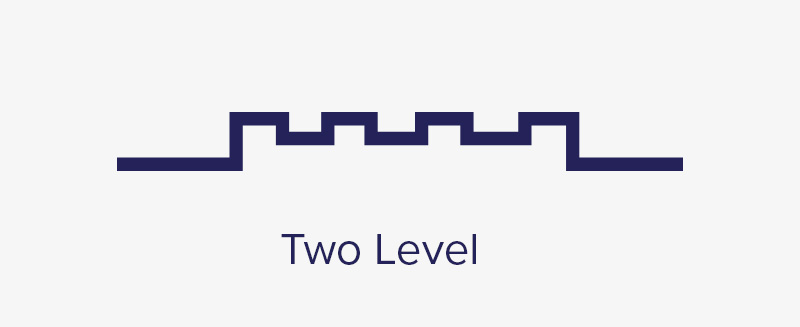

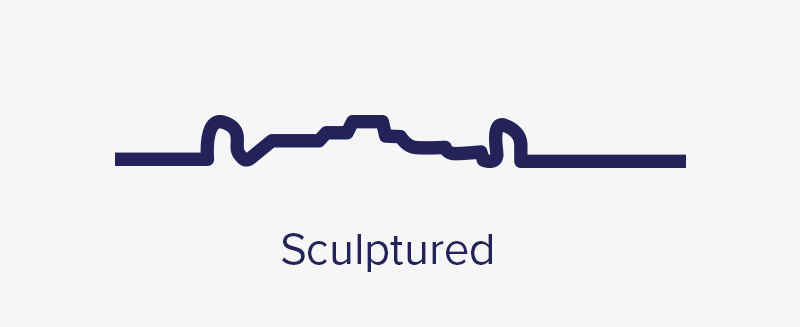

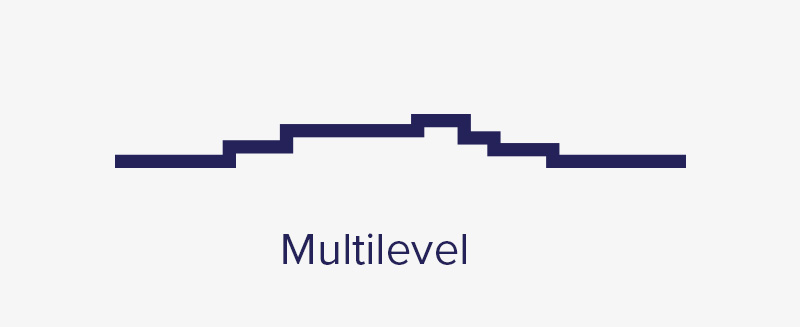

Relief Pattern Configurations

Press Types of Embossing/ Debossing

Clamshell press

Derived from the similarity of an opening and closing clamshell, paper is placed between dies to create an emboss/deboss effect.

Straight stamp press

Like a stamp, single sheets of paper are fed between dies and are imprinted to create an emboss/deboss effect.

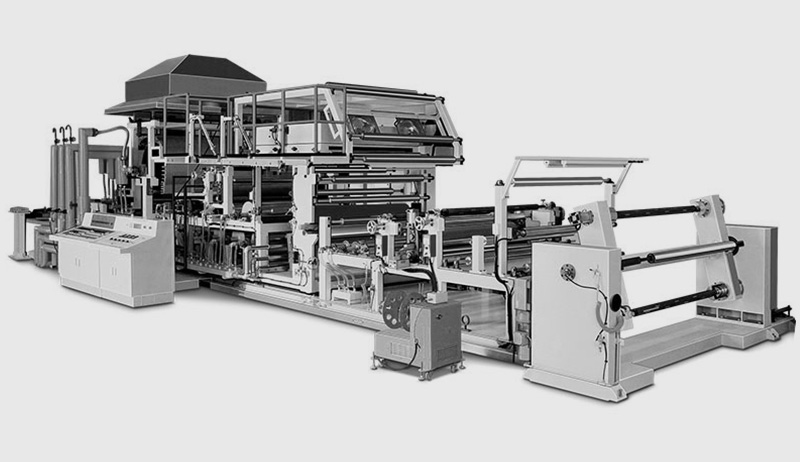

Roll press

Large paper rolls are fed through between dies continuously to emboss/deboss designs faster than other traditional methods.

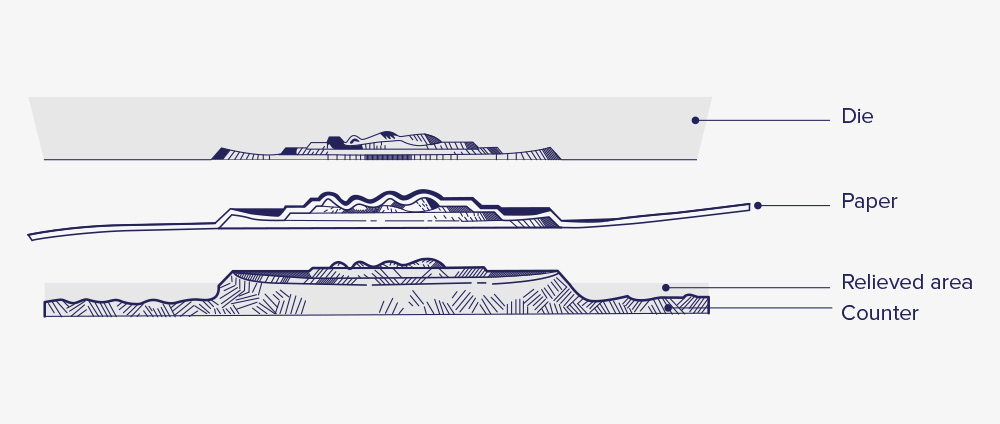

Embossing/ Debossing Die

Embossing/Debossing Die

Two opposite dies that fit together like puzzle pieces, embossing and debossing dies feature a mirrored image of the custom design, one being raised and the other sunken into the die to create the desired look.