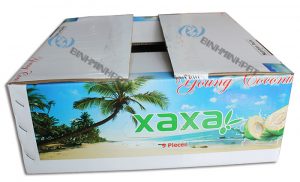

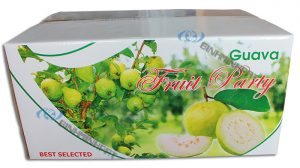

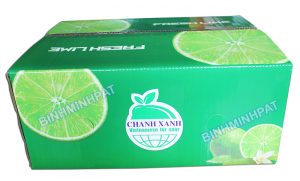

Custom carton boxes, corrugated boxes

Upgrade your custom printed shipping boxes

Create your ideal packaging with endless customization options to design the perfect packaging for your product.

Aqueous Coating

Popular for being fast drying and creating surfaces that are soft to the touch, aqueous coatings are water based and makes for a great eco-friendly

UV Coating

Cured by exposure to ultraviolet light, UV coatings are fast drying and provide the highest quality gloss or matte finishes available. Ideal for improving surface

Spot Gloss UV

UV coating is applied to specified areas to create unique and eye catching designs. Ideal for enriching text or designs, spot UV coatings are commonly

Soft Touch Coating

Popular for its velvety finish, soft touch coatings are fast drying and finger print resistant, making them ideal for communicating luxury and elegance. Best Used

Varnish

A cost effective alternative to coatings, varnish is applied the same way CMYK inks are applied and provide a glossy, matte or satin finish to

Lamination

Lamination adheres a protective film to the surface of packaging materials to maximize strength, durability and provide a barrier to avoid any water damage to

Anti-scratch lamination

Anti-scratch lamination is exactly what it sounds like. Using a BOPP film, this lamination type is scratch resistant and cost effective. Best Used With Overview

Soft touch / Silk Lamination

Soft touch/silk lamination, provides a matte finish that is soft to the touch. Similar to peach skin, the surface features a velvety texture that adds

Oil Based Inks

Oil based inks may be comprised of soy, vegetable or mineral oi, hydrocarbons and pigment to create inks that provide high quality color output for

Soy/Vegetable Based Inks

Compared to traditional petroleum-based inks, soy-based ink is a blend between soybean oil and pigment. It is eco-friendly and provides excellent color vibrancy and accuracy

Water-based Inks

A simple concoction of water and pigment, water based inks are an extremely effective, eco-friendly alternative for creating sustainable printing solutions. Ideal for printing on

Pantone

Pantone is a universal color matching system categorized by number and name. This allows brands to conveniently create consistent color schemes that are true to

Pantone Metallic

Pantone Metallic is a range of colors matched to metallic sheens. Ideal for creating consistent brand color schemes and designs, the pantone metallics color matching

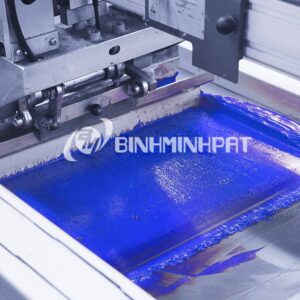

Silk Screen Print

Popular for printing labels and graphics onto various packaging types, screen/silk printing is used across many different industries for its exceptional quality output. Best Used

Flexography Print

Flexography is a printing technique that provides optimal efficiency, flexibility and consistency to any project. Popular for the fast drying ink it uses, flexography is

UV Print

Using ultra violet light to cure inks, UV printing is very popular for a wide range of retail and luxury packaging applications. UV printing leaves

Clay Natural Kraft (CNK)

Made from recycled material, CNK paper features a matte, clay coated front side and a brown kraft back side. The clay coating offers more dimensional

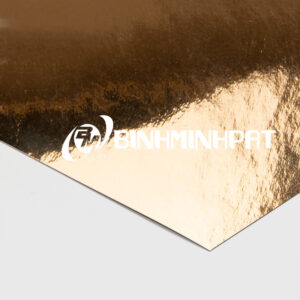

Metallic Paper

This speciality paper features a metallic finish that can be coated to be matte or glossy. Most commonly used as a decorative paper, metallic paper

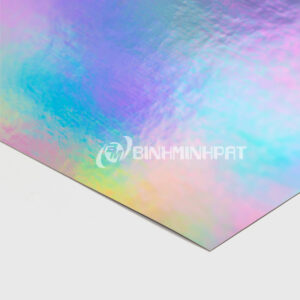

Holographic paper

Made from laminated paperboard, holographic paper is an eye-catching material used for packaging cosmetics, apparel and much more. This paperboard emulates a 3D effect, showing

Textured paper

Textured paper is a premium grade paper stock that features a textured surface for high quality printing and finishing. Ideal for creating luxury paper bags

C Flute

The most common flute option for shipping and mailer boxes, C flute corrugated board offers excellent compression properties and crush resistance for e-commerce products. Best

A Flute

Providing excellent compression and stacking resistance, A flute corrugated board provides support and protection to fragile and heavy weight products. Best Used With Overview Known

B Flute

Commonly used as additional packaging material such as corrugated box inserts, B flute corrugated board offers excellent crush and puncture resistance. Best Used With Overview

F Flute

F fluting provides corrugated board with a thin and stiffer construction, popular in the fast food, cosmetics and jewelry industries for corrugated clamshell packaging. Best

Combination Embossing

A combination between embossing and foil stamping, combination embossing creates 3D designs that feature a metallic finish. The image, design or text is embossed and

Registered Embossing

Registered embossing places a blind embossed image with another element created using ink, foil or another embossed image to create a unique 3D design. Best

Blind Debossing

Blind debossing presses designs and text into paperboard to create an engraved look. Ideal for creating unique artwork designs, debossing is popular across a wide

Blind Embossing

Blind embossing presses logos and text into paperboard to create a 3D design that customers can see and feel. Ideal for creating cutting edge artwork

Cold Foil Printing

A UV curable adhesive is printed in the shape of designs or text for foil to be pressed onto the adhesive. Ideal for decorating brand

Hot Foil Stamping

Hot foil stamping uses heat and pressure to apply metallic detailing to enhance brand logos or packaging artwork designs. Commonly used for applications in luxury

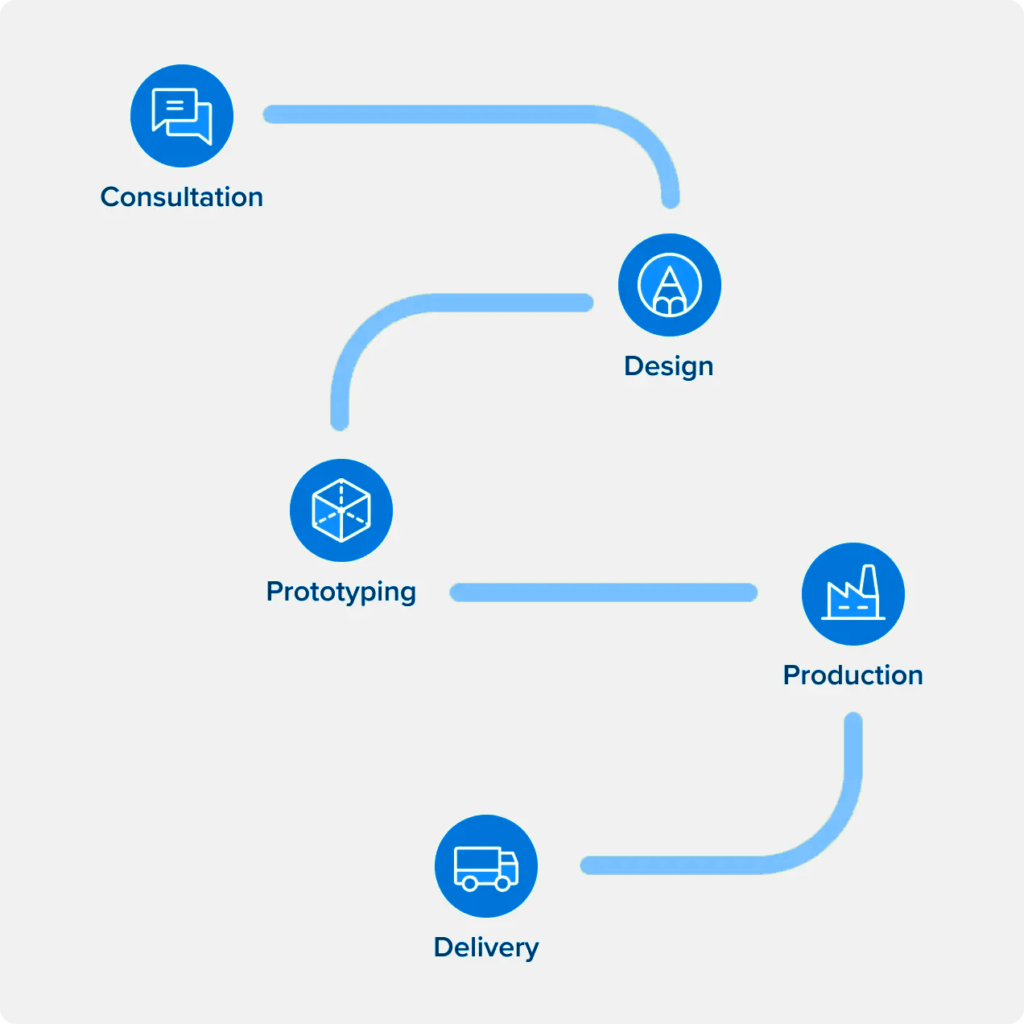

End-to-end solution to carton packaging

More informed decisions

Streamline process

Cost effective

Add extra security with engineered inserts

Are you shipping products that are prone to damage? Want to lower your overall cost of returns? Get custom engineered inserts that are designed specifically to the shape of your products. Custom inserts are great to add to your corrugated shipping boxes to firmly secure your products in place during shipping!

Reliable folding carton manufacturer

Service support where you need it

Consultation

Unlock the perfect package with our packaging experts! Get guidance on every step of your journey and make sure you get just what you need.

Production

Let our experts manage your production journey from start to finish – they’ll source the best materials and guarantee impeccable quality — a hassle free experience.

Design

Looking to launch a stunning new design or take an existing one up a notch? Our team of pros can elevate your artwork and structural designs to extraordinary levels.

Logistic

Rest easy knowing that our expert logistics team has you covered when it comes to shipping. Get organized and save more with custom plans tailored for your needs!

Prototype

Worried about your packaging prototype? Check out our range of flexible options to try before committing to mass production. Try it risk-free and save yourself time.

Optimize

Discover the power of our optimization strategies, which can help you lower your time and cost spent on packaging while also improving sustainability!

Inspiring Stories from Our Customers

Contact Information:

BINH MINH PAT PAPER PACKAGING COMPANY

Head Office: Lot A59/I, Street No. 7, Vinh Loc Industrial Park, Binh Tan District, Ho Chi Minh City

Phone: +8428 6679 5362 – Hotline: +84 916 660 853

Manufacturing Plant:

Address: Lot B26, Street No. 2, Hai Son Industrial Park, Duc Hoa District, Long An Province

Phone: +84272 3775 518~19 – Hotline: +84 918 000 768

Email: info@binhminhpat.com – Website: www.binhminhpackaging.vn

Frequently Asked Questions (FAQs)?

What is the difference between cardboard and corrugated boxes?

The main difference lies in the construction of the material. Cardboard is made from thick stock paper and is commonly used to create packaging for smaller and lighter weight retail products. Corrugated packaging materials on the other hand are more durable and are made from 3 layers of paperboard, 1 layer of corrugated paper sandwiched between two liner boards. Corrugated packaging is most popular for shipping thanks to its sturdy and durable construction.

What is the minimum order quantity for corrugated boxes?

Our MOQ for corrugated packaging currently stands at 500 units. To ensure you are getting the most out of your packaging supply, we recommend placing large orders to keep your cost per unit as low as possible!

Please refer to the list of all product-specific MOQs or contact us via phone or email for more details.

What corrugated box styles do you offer?

We carry a wide range of corrugated packaging styles to choose from. Some of our most popular options include:

- Mailer boxes

- Regular slotted boxes

- Tab lock roll end boxes

- Carrier boxes

However, if you are not seeing a particular style that fits your needs, our structural engineering team can custom design a structure based on your needs. Contact us here to get started.

Can corrugated boxes be recycled?

Absolutely! All corrugated packaging can be recycled and is made from recycled material; however, this may change based on the coatings and inks you add to your packaging.

As a general tip, if you are looking to be more sustainable and avoid any possibility that your packaging is not fully recyclable, we recommend going with vegetable inks for printing. This ensures that your corrugated packaging is not only recyclable but also safely biodegradable!

What is the turnaround time for custom printed corrugated boxes?

Our average turnaround time for custom printed corrugated packaging is 15 – 20 business days. However, things may vary depending on the complexity of your packaging project. Make sure to check in with a dedicated product specialists for more tailored time estimates.

What coatings work best for corrugated packaging?

Kraft corrugated boxes are sturdy and food safe, so no varnish or coating is required.

However, corrugated packaging can still cosmetically benefit from coatings to enhance artwork designs. Varnish and Aqueous (AQ) coatings are most popular for corrugated packaging.

AQ coating is a water-based coating that is fast drying and eco-friendly. On the other hand, Varnish is not eco-friendly but provides an optimal moisture barrier to protect your products and artwork designs. Both AQ coatings and Varnishes allow for either a matte or glossy finish.